The push to reach net-zero carbon emissions is an important goal for businesses and organizations around the globe, and ports and the companies they do business with are no exception. Now, with technology advancing steadily, those aspirational goals are turning into reality, putting ports and their partners firmly on the path toward environmental sustainability.

Here’s a look at how four major North American ports are taking action to become carbon neutral and curb emissions of other greenhouse gases.

Charging Stations in the Garden State

It’s still fairly rare to see an electric truck pull into the Port Newark Container Terminal, but the Port Authority of New York and New Jersey (PANYNJ) expects that to change in the near future, so it’s getting ready now.

A project to install four electric-truck charging stations at the Port Newark Welcome Center is in the design phase and likely will be completed next year, according to Christine Weydig, the port authority’s director of sustainability. The 350-kilowatt stations will allow for fast “opportunity charging” and the layout will accommodate trucks with trailers, she said.

Building out that infrastructure will help to address “range anxiety,” a primary barrier to the adoption of electric trucks, Weydig said. As trucking companies see more charging infrastructure in place, they’ll be more likely to convert their fleets to zero-emission vehicles, she said.

“This installation is meant to help kickstart a transition to electric drayage trucks visiting PANYNJ ports and simultaneously create more demand for public charging to catalyze private investment,” Weydig said.

That project is just one component of PANYNJ’s plan to become carbon neutral by 2050, a goal that applies not only to the port authority itself but to its tenants, business partners and customers. To identify priorities, PANYNJ performs an annual inventory of emissions and ranks the operational areas that contribute the most to that total. Within its seaport business, trucks top the list, followed by ocean-going vessels, cargo-handling equipment and buildings onsite.

PANYNJ’s plan includes each of those four areas. Its Clean Vessel Incentive Program provides financial incentives to operators, charters and agents of oceangoing vessels that upgrade their engine, fuel and technology. The enhancements reduce emissions beyond the regulatory standards set by the International Maritime Organization.

Under the program’s scoring system, vessels earn points when they slow-steam at 10 knots or less within 20 nautical miles of the territorial sea line. They also earn points based on the vessel’s Environmental Ship Index score and for meeting Tier III standards for cleaner engines.

Meanwhile, PANYNJ is gradually phasing out diesel-powered material handling equipment. Beginning last January, only equipment that meets stringent Tier 4 emissions standards may be added to existing fleets of equipment serving marine terminals. In addition, new ship-to-shore cranes and rail-mounted gantry cranes have to be zero-emission.

Beginning Jan. 1, 2023, almost all terminal and yard tractors will have to meet Tier 3 emissions standards, and almost all material-handling equipment must meet Tier 2 standards. By 2026, almost all terminal tractors and material-handling equipment added to existing fleets will have to be zero-emission.

As for buildings onsite, PANYNJ recently provided funding to upgrade the lighting systems for three marine terminal tenants. Maher Terminal, Millennium Marine Rail and APM Terminals are upgrading more than 200 antiquated high-mast light poles with LED fixtures at a total cost of about $8 million, Weydig said.

“We really take seriously our ability to influence our tenants, stakeholders and customers to lead by example, and we recognize that a lot of our business partners have their own net-zero goals, so we’re looking to see how we can enable them and accelerate that transition,” Weydig said.

Sticking to the Schedule in Virginia

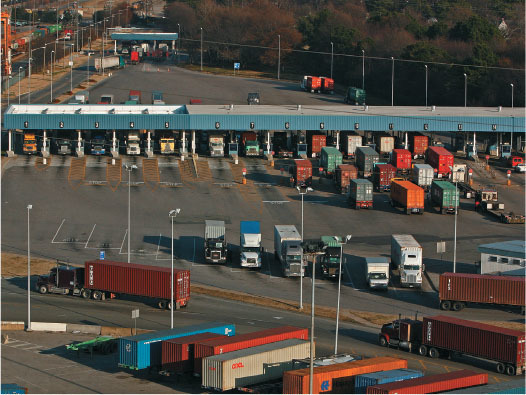

Truck drivers visiting the Port of Virginia for the first time might be surprised when they’re able to get into and out of the port’s two main container terminals in about 45 minutes, or even less. Since 2018, the port’s PRO-PASS Truck Reservation System has allowed drivers to use an online portal to make appointments to pick up containers, preventing long queues from forming at the gates and thereby reducing emissions.

“In the beginning, there was a lot of resistance from motor carriers, but now they’re seeing the value in it because it ensures quicker truck turn times for them,” said Joseph D. Harris, senior director for media relations at the Virginia Port Authority (VPA).

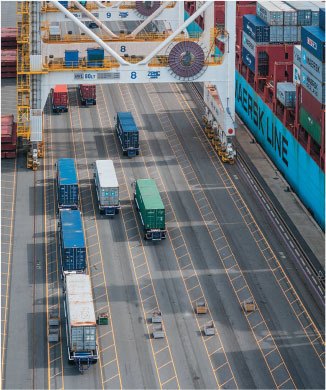

The port’s semi-automated rail-mounted gantry cranes speed up turn times even more by “grooming” container stacks overnight, Harris said. Using an advanced software system, the cranes move containers meant to be exported closer to the port berth, and they move imported containers from the berth area to the front of stacks. Containers with the earliest appointment times are placed upfront to boost throughput.

Those initiatives are part of VPA’s goal to become carbon neutral by 2040. Last year, 33% of the material-handling equipment at the port was electric and 16% was hybrid, according to the port’s 2021 environmental sustainability report. As a result, the port has reduced its greenhouse gas emissions 30% since 2017, the report said.

In 2021, 58% of the port’s shuttle and straddle carriers were hybrid, according to the report. Each hybrid shuttle results in 90% lower nitrous-oxide emissions and 50% less diesel fuel consumption than a traditional diesel unit.

VPA also wants to continue to grow its Richmond barge service, which in fiscal year 2022 eliminated more than 76,000 roundtrip truck trips, primarily from the interstate connecting Norfolk Harbor and the Richmond Marine Terminal. In 2019, the port’s air-quality inventory showed that the barge service eliminated 3,671 tons of ozone pollutants.

Since 2008, the barge service has connected the port’s deep-water container terminals in Norfolk Harbor to the Richmond Marine Terminal. The service runs three days a week, moving containers farther inland toward their destinations more efficiently than trucks. The Port of Virginia has the capacity to expand that service to five days a week to accommodate demand, Harris said.

In May, the port announced plans to get all of the electricity it needs for operations from clean-energy resources by 2024, shaving eight years off its original goal. Solar, nuclear and wind resources from Dominion Energy will provide the port’s current load of about 130,000 megawatt-hours of electricity each year, as well as increased loads in the future, Harris said.

Newer Trucks Rule in Vancouver

If your truck is an old clunker, then you’ll have a hard time entering the Port of Vancouver in British Columbia. In 2008, the port began implementing stringent environmental requirements for container trucks, including a provision requiring trucks with 2006 engines or older to have an approved emissions-control device that reduces particulate matter by 20% to 25%.

Beginning this year, trucks that are more than 10 years old aren’t permitted to access the port, according to Arpen Rana, spokesperson for the Vancouver Fraser Port Authority. The regulation is just one part of a broad plan to phase out port-related emissions by 2050.

Under the port authority’s Non-Road Diesel Emissions program, established in 2015, tenants must report and label all nonroad diesel equipment and pay fees on older, higher-emission equipment. When older equipment is replaced, upgraded or retrofitted, up to 80% of those fees are rebated to the tenant, provided the company has a fuel-efficiency plan in place that includes an idle-reduction policy.

Through the port authority’s EcoAction Program, shipping companies can qualify for up to 47% off their harbor dues fee by implementing sustainability measures, including using renewable energy, installing propeller technologies that reduce underwater noise or obtaining third-party environmental designations.

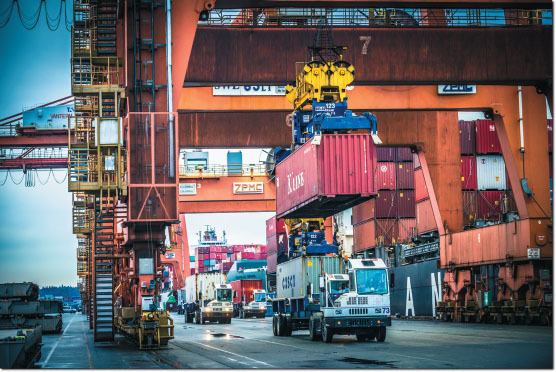

In the past few years, the port authority has conducted several pilot programs to test new technology. In 2020, the group partnered with Seaspan Ferries to have one vessel use 100% biodiesel fuel for a month while transporting containers across the Georgia Strait. Last year, the port began testing two battery-electric-powered terminal trucks from European manufacturer Terberg at Seaspan’s Tilbury Marine Terminal on the Fraser River.

Since 2015, the port authority has partnered with the Vancouver-based environmental- consulting firm Climate Smart to help port tenants conserve energy and reduce emissions. Through the Climate Smart program, businesses conduct an emissions inventory to calculate their output and then create an action plan to reduce those emissions.

So far, 24 tenants have gone through the process, resulting in greenhouse gas reductions of 6,087 tons, Rana said.

The port’s shore-power installations have resulted in even bigger reductions. The technology enables ships to shut down their diesel-powered auxiliary engines and plug into land-based electrical power, an especially green alternative given that electricity at the Port of Vancouver comes primarily from hydroelectricity. Since 2009, shore power at the port’s cruise-ship and container terminals has eliminated 25,495 tons of greenhouse gas emissions, Rana said.

Testing New Technology in Los Angeles

The Port of Los Angeles has been the busiest port in the Western Hemisphere each year since 2000, and last year was its busiest yet, with 10.7 million 20-foot equivalent units (TEUs) handled.

Reducing the carbon footprint of such a massive operation requires a robust, multipronged approach, so the port has participated in at least 16 sustainability research projects over the past few years, with many more planned for the future, according to Chris Cannon, director of environmental management and chief sustainability officer.

Last year, about 28% of the 1,915 pieces of cargo-handling equipment at the port, including cranes, yard tractors and other off-road vehicles, ran on electricity or alternative fuels, Cannon said.

The port wants to eliminate tailpipe emissions from cargo-handling equipment by 2030 and from drayage trucks by 2035. Those goals are essential to the port’s larger objective of reducing port-related greenhouse gas emissions 40% below 1990 levels by 2030, and 80% below 1990 levels by 2050.

In January, the Port of Los Angeles, Port of Shanghai and C40 Cities Climate Leadership Group announced a partnership to create the world’s first transpacific green shipping corridor. The ports and their partners, including shipping lines and cargo owners in the United States and China, have committed to develop a plan by the end of the year to decarbonize one of the world’s busiest cargo routes.

The plan will call for the phasing in of low, ultra-low and zero-carbon-fueled ships throughout this decade, with shipping lines voluntarily introducing the world’s first zerocarbon transpacific container ships by 2030.

The partnership also aims to develop best management practices to reduce emissions and improve efficiency for all ships using this international trade corridor. Similarly, the group will work to reduce emissions from port operations, improving air quality in two of the world’s urban centers most affected by air pollution.

“In the past, we’ve always had programs that have focused on the port itself,” Cannon said. “Now, we want to focus on the entire journey. We want to integrate our efforts to reduce emissions at the ports into an overall program to reduce emissions all the way across the ocean.”

Cannon said the Port of Los Angeles is serving as a proving ground for new technologies. In 2019, the port began testing the world’s first zero-emission top handler, powered by a 1-megawatt battery designed to operate for 18 hours between charges. A next-generation top handler improving on that design likely will be tested at the port later this year, Cannon said.

With its partners, the port is exploring tugboats powered by hydrogen fuel cells and zeroemission switcher locomotives. Next year, the port will begin testing 10 electric yard tractors that use inductive charging, also known as wireless charging or cordless charging, Cannon said. The tractors will be parked atop a charging station instead of having to be plugged in, similar to how inductive pads charge cellphones and other portable devices.

“Every chance we get, we’re going to try to push the envelope and test more pieces of zero-emission equipment,” Cannon said.

Strengthening Net Zero GHG Initiatives

As part of AAPA’s efforts to take a leadership stance in the fight against climate change, AAPA has been proactively looking for ways to strengthen and contribute to decarbonization initiatives – and found two good fits: Blue Sky Maritime Coalition and PortVision50.

AAPA joined as a founding member of the Blue Sky Maritime Coalition. The coalition’s mission is to accelerate the transition of waterborne transportation in the United States and Canada toward net-zero GHG emissions.

Also, AAPA has partnered with PortVision50, an organization that helps maritime stakeholders understand the technical and operational solutions available to the industry for achieving the goals of the International Maritime Organization (IMO) GHG Strategy.

Working with North American ports and other maritime stakeholders to understand the mix of technical, operational and innovative solutions applicable to cargo ships, PortVision50 is in full force to ensure that port infrastructure projects align with global projects supporting IMO GHG reduction targets for 2030 and 2050.

AAPA Seaports

AAPA Seaports